Some of the properties of thermoplastics are:

• Specific gravity: This is the ratio of the density of the thermoplastic to the density of water. It indicates how heavy or light the thermoplastic is. For example, polyethene has a specific gravity of 0.95, which means it is lighter than water, while polyvinyl chloride has a specific gravity of 1.4, which means it is heavier than water.

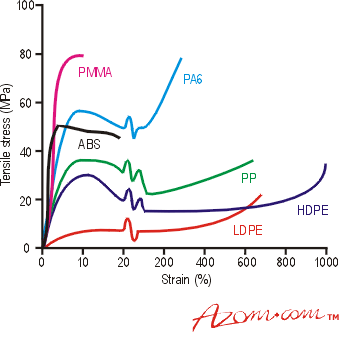

• Tensile strength: This is the maximum stress that the thermoplastic can withstand before breaking when stretched. It indicates how strong or weak the thermoplastic is. For example, polypropylene has a tensile strength of 8,000 psi (pounds per square inch), which means it can resist a lot of force, while polyethene has a tensile strength of 3,200 psi, which means it can break easily.

• Tensile modulus: This is the ratio of stress to strain within the elastic region of the thermoplastic. It indicates how stiff or flexible the thermoplastic is. For example, polystyrene has a tensile modulus of 410,000 psi, which means it is very rigid and does not deform much when stretched, while polybutylene has a tensile modulus of 55,000 psi, which means it is very flexible and can bend a lot when stretched.

• Coefficient of linear expansion: This is the amount of change in length per unit length per degree change in temperature. It indicates how much the thermoplastic expands or contracts when heated or cooled. For example, polyethylene has a coefficient of linear expansion of 90 x 10^-6 in/in oF, which means it expands a lot when heated and contracts a lot when cooled, while polyvinyl chloride has a coefficient of linear expansion of 30 x 10^-6 in/in oF, which means it does not change much in size when heated or cooled.

• Thermal conductivity: This is the rate at which heat flows through the thermoplastic. It indicates how well or poorly the thermoplastic conducts heat. For example, polyethene has a thermal conductivity of 3.2 Btu in /ft2 h oF, which means it is a poor conductor of heat and can insulate well, while polystyrene has a thermal conductivity of 1.1 Btu in /ft2 h oF, which means it is a better conductor of heat and can dissipate heat faster.

• Specific heat: This is the amount of heat required to raise the temperature of one pound of the thermoplastic by one degree Fahrenheit. It indicates how much heat the thermoplastic can store or release. For example, polyethene has a specific heat of 0.55 Btu/lb oF, which means it can store a lot of heat and keep its temperature stable, while polystyrene has a specific heat of 0.25 Btu/lb oF, which means it can release heat quickly and change its temperature easily.

• Maximum temperature limit: This is the highest temperature that the thermoplastic can withstand without losing its properties or degrading. It indicates how resistant or sensitive the thermoplastic is to high temperatures. For example, polyvinylidene fluoride has a maximum temperature limit of 300 oF (150 C), which means it can endure very high temperatures without melting or decomposing, while polyethene has a maximum temperature limit of 160 oF (70 C), which means it can melt or degrade at relatively low temperatures.